An inland waterway shuttle – a new transport option for heavy-load and project cargo organised by the Am Zehnhoff-Söns Group in cooperation with BLG LOGISTICS and a company from the construction machinery industry – has been running regularly between the ports of Bremen and the inland areas of western Germany since March.

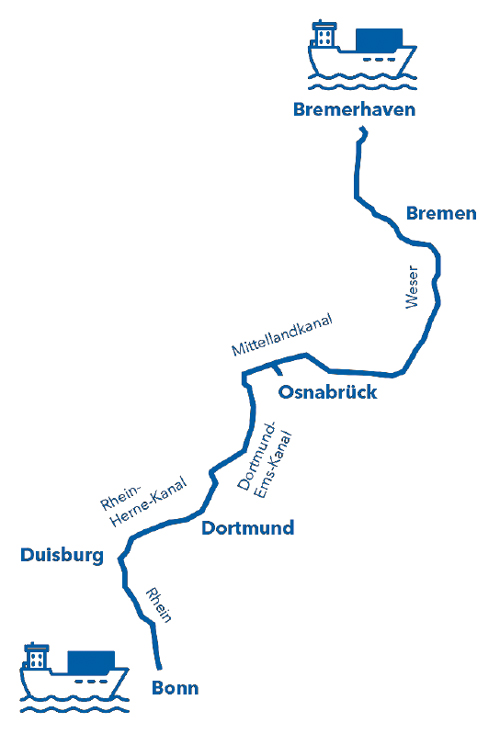

The partners have planned a transit time of around six days for the route via the Rhine, the Mittelland Canal and the Weser. “In our planning, we first had to get used to the fact that inland shipping operates a little differently to maritime shipping,” explains Prokopp as she outlines the coordination discussions that took place. “It’s in operation 24/7 and you have to say goodbye to weekends off. However, it all worked out quickly and smoothly in the end.” In turn, the shuttle is highly flexible. “Whether from Neuss, Krefeld, Duisburg, Dortmund or Osnabrück – potential shippers can request individual stops and partial loads from us or BLG along the route,” explains Thomas Keppelstrass, Manager Project Cargo & Sales Conventional at Am Zehnhoff-Söns GmbH. “If there’s enough demand for it, it’s also possible to connect the Moselle and Saar to Bremerhaven.” The partners then check which nearby harbour has the appropriate loading infrastructure, including a crane, and arrange everything else.

When asked about their aims for the new shuttle, Prokopp and Keppelstrass have differing priorities. “Our aim is to establish a regular connection from the inland to the ports of Bremen, ideally as a shuttle service. And, as the situation stands so far, I’m sure that the shuttle will still be with us in three years’ time,” says Prokopp. The manager from Bonn wholeheartedly agrees. “I’d also like us to be able to increase the frequency of the shuttle from one to two departures a month by the end of this year.”

One of the ways this could be achieved is by attracting new customers, which Prokopp and her team are already working hard to do. “We can also take containers on board where required or transport wind power components to the hinterland,” she says. “I can’t imagine that much will change in the near future in terms of the numerous construction sites and congested motorway bridges in Germany,” she continues with a wink when asked about the current road situation. “Plus, the authorisation procedures for heavy goods transport certainly won’t get any easier or less complicated. An inland waterway vessel with a load capacity of around 1,600 tonnes is a sensible alternative.” The two partners will also be answering questions about the new heavy-load shuttle at transport logistic, which takes place in Munich from 2 to 5 June. (bre)