Where exactly are we on our path towards digitalisation and automation, and where will it take us? Where are the stumbling blocks, and what’s the best way to advance digitalisation? One thing is clear – speed isn’t everything, but we shouldn’t underestimate it either.

Sabine Nollmann, bremenports (4x), Nports, JWP,

NPorts Andreas Burmann (2x), Nports

Smart digitalisation is key for the maritime industry and logistics. However, assessments differ as to whether progress is being made fast enough or whether we need to play catch up. For example, the assessment made by Bitkom, the German information and telecommunications sector’s industry association, is positive. They describe German logistics as “a digital pioneer”, adding that the majority of logistics companies here are “well-positioned, technologically speaking”. The “Digitalisation Index for SMEs 2020/2021” telecommunications study drew similar conclusions, designating transport and logistics companies as crisis-proof and being prepared to increase their investments in digitalisation projects.

The “Digitalisation Index 2022”, published by the Federal Ministry of Economics and Climate Protection, gives a slightly different impression, stating that the German economy became only slightly more digital in 2022 compared to 2021. According to the report, it would be reasonable to say that digitalisation in 2022 had stagnated, given the strong increase in 2021. The front-runners in digitalisation last year were the information and communication technology sector and vehicle manufacturing, whereas the transport and logistics sector’s development here was significantly below average. Optimists see these study results as good news – the German economy has not taken any steps backwards where digitalisation is concerned. Pessimists, however, feel vindicated in their view that digitalisation in this country is proceeding at a snail’s pace at best..

Holocher and Freitag feel the need for action

“Numerous studies show that Germany isn’t exactly spearheading European digitalisation,” said Klaus Harald Holocher, Professor of European Transport Economics and Port Management at Jade University of Applied Sciences, when assessing the current situation. “In my view, the local ports are on the right track, they’re just too slow. To make faster progress, the German government and the coastal states, their authorities and the maritime industry would have to work together more closely and quickly, with more focus on the benefits, such as cost and efficiency gains, than on the General Data Protection Regulation.”

“On the one hand, there are some innovative companies with lighthouse projects,” added Michael Freitag, Executive Director of BIBA – Bremen Institute for Production and Logistics. “On the other, though, the state of digitalisation in SMEs varies greatly. For me, the problem in the logistics field is that classic logistics service providers and terminal operators are very focused on their daily business. There are isolated projects and implementation of prototypes, but often no overarching digitalisation concept.” In his view, cooperation and networking between the main figures within the logistics chain is particularly lacking, which is why he believes there to be a “real need for action” where German ports are concerned.

“Germany isn’t exactly spearheading European digitalisation.”

Klaus Harald Holocher, Professor of European Transport Economics and Port Management at Jade University of Applied Sciences

“Ports must adapt to the climate”

It is precisely with this progressive view that Stefan Färber, Head of Port Development and Innovation at bremenports, identified a close connection between digitalisation and sustainability. “The ports of the future are digital connectors,” he stated. “They are intelligent and networked transhipment points, partly with autonomous and automated processes. Digitalising the entire supply chain, with zero emissions or with the smallest possible carbon footprint, is conceivable.” Together with the Internet of Things (IOT) and the application of artificial intelligence (AI), he identifies Big Data as the most important future technology for this. “These developments have made the world many times more dynamic and presented the maritime industry with the challenge of offering better solutions more quickly and easily,” he added.

The ports of Bremen have embraced this challenge and, with the “Port Development Concept 2035”, published last year, and the SmartPort campaign launched in April (see page 29) have, following intensive cooperation with all relevant stake-holders, charted an important course towards digitalisation. “The role of the port authorities has changed,” emphasised Färber, with this in mind. “The lessors have become proactive instigators who bring the individual players in the port together and participate in interdisciplinary projects.” In addition, he believes that the importance of the ports will continue to grow as Germany’s energy supply is secured. “If the energy transition through the use of hydrogen and its derivatives is to succeed, the ports will also play a major role in supplying the nation with energy. As part of the ‘green transformation’, the port infrastructure must also adapt to the changing climate,” he continued.

Involve all stakeholders early on

Hendric Maasch, Head of Commercial Affairs at NPorts and JadeWeserPort, also sees a correlation between digitalisation and the climate. “In the port of the future, we’ll use digital progress in almost all areas,” he outlined. “The efficiency of the ports will essentially depend on systematic data mining and will be shaped by developments in sensor technology and simulation. This will benefit logistical processes, safety and operational readiness, as well as the environment and the climate,” he continued. In his view, digital technologies that are able to process and visualise the results obtained through data mining or AI, in a way all decision-makers can understand, will be in particular demand. Like Färber, Maasch considers it inevitable that all stakeholders will be involved in this development process from the get-go. “The great art of shaping the digital transformation is in bringing people along with us and making them understand the advantages of digitalisation. This is something we should be doing every day,” he concluded.

In this context, Holocher emphasises that processes should not be modified in a one-size-fits-all approach. Instead, it is important to tailor the processes to the fluid possibilities and requirements of digitalisation. “Otherwise, the process will be cumbersome and lengthy,” he said. “In the port, we also talk in terms of ‘bullshit in, bullshit out’ in such cases.” In his opinion, the Eurogate Container Terminal Wilhelmshaven (CTW), which is currently converting its container handling from a manual system to an automated one, is on a good path. “After several years of Eurogate testing the introduction of driverless van carriers and straddle carriers, CTW is currently converting to double-trolley container gantry cranes operated by Automated Guided Vehicles (AGVs). There will also be an automated warehouse service,” said Holocher. “In the not-too-distant future,” he added, “it should also be possible to operate the container gantry cranes without a driver through remote control. For this to work, robust sensors will have to be used and I suspect some legal regulations will need to be adapted.”

“Classic logistics service providers and terminal operators are very focused on their daily business.”

Michael Freitag, Executive Director of BIBA – Bremen Institute for Production and Logistics

“The ports of the future are digital connectors; intelligent and networked transhipment points.”

Stefan Färber, Head of Port Development and Innovation at bremenports

“No fully automated ports”

“The vision for the future is the SmartPort, with autonomous cranes, carriers and AGVs, as well as a digital twin of the physical processes,” explained Freitag when speaking about the port of the future and the technologies used there. “This, in turn, will be connected via platforms to both the upstream and downstream processes and to stakeholders.” However, he feels there will be no fully automated ports, as situations will always arise in day-to-day business where people are indispensable. “Plus, it’s precisely for these interactions between humans and autonomous systems that new processes and interfaces have to be created,” he continued. “I feel that this as an important research and development task for the next few years.”

Showcase projects in Lower Saxony and Bremen

A multitude of different digitalisation and automation projects currently being worked on in the ports of Bremen and Lower Saxony, with the aim of ensuring the sites’ long-term survival, demonstrate what possible paths to the “port of the future” might look like. Indeed, as they know that the appropriate solutions cannot only increase handling figures and efficiency, they can also simplify complex processes, minimise waiting times and reduce energy consumption. It has also been shown that introducing new technologies guarantees better digital networking between all participants in the maritime transport chain.

Where Bremen is concerned, the Port Information and Operation System, or “PRINOS” for short, the intelligent port logbook “Port2Connect” and the previously mentioned SmartPort culture feature among the showcase projects. “PRINOS” is a customer portal with a modular system structure that has been supporting Bremische Hafeneisenbahn in capacity planning, scheduling and payroll accounting since 2022. The intelligent portal ensures smooth communication between all authorised users, shunting service providers and terminals using what is known as a TAF-TSI interface for the digital transmission of data. “Port2Connect” was launched in January this year and includes a digital, smart port logbook that monitors ships – for example, by determining position data through the use of an accurate radar measurement system, which is then made accessible using AI and machine learning methods – during their time in the port. This should enable efficient and sustainable use of the port infrastructure and contribute to environmental protection efforts. The “SmartPort” project, which has already been mentioned, is of a much higher order. Indeed, bremenports is using it to achieve their goal of improving the performance of Bremen’s ports through networking and digital solutions in close cooperation with the stakeholders. Among other things, a SmartPort community is to be established in four phases, between April this year and February 2024, and will proactively help shape the digital future of the ports and develop a SmartPort strategy with concrete actions.

“The great art of shaping the digital transformation is in bringing

people along with us.”

Hendric Maasch, Head of Commercial Affairs at NPorts and JadeWeserPort/p>

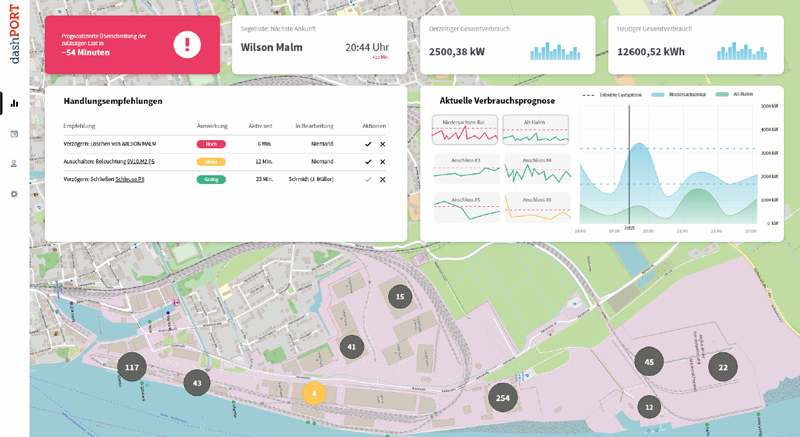

The “dashPORT” digital control centre was successfully completed in Brake in September 2022. This project involved the development of a software solution that visualises both energy consumption and energy consumers throughout the port. The findings can help derive suitable measures for reducing energy consumption and CO₂ emissions in each case. The pilot project, which NPorts, the Fraunhofer CML, the Oldenburg OFFIS Institute and J. MÜLLER AG implemented together, was awarded first prize in the “How can ports and maritime logistics be made more sustainable?” category at the Maritime Cluster Northern Germany’s “MCN Cup 2021”.

This screenshot shows how the “dashPORT” digital control centre in Brake visualises energy consumption and energy consumers in the port.

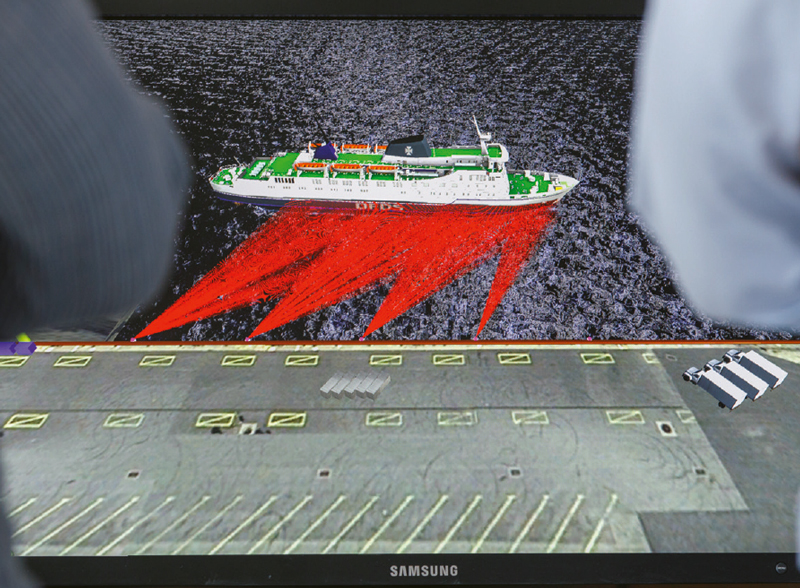

“SmartKai” is a parking aid for ships. Our photos give an impression of how the sensor (front) “catches” a ship in Cuxhaven and how this process is then displayed on the monitor.